Maker Tip: Measuring and Marking

Have you ever measured something – like a piece of pipe or lumber, and then cut it to length, but it came out just a skosh or smidgen too short?

“Measure twice, cut once” the old proverb Norm Abram always emphasizes is still sound, but here is my more practical statement for everyday use:

“If you don’t measure anything, you will not make a measuring mistake.”

Me

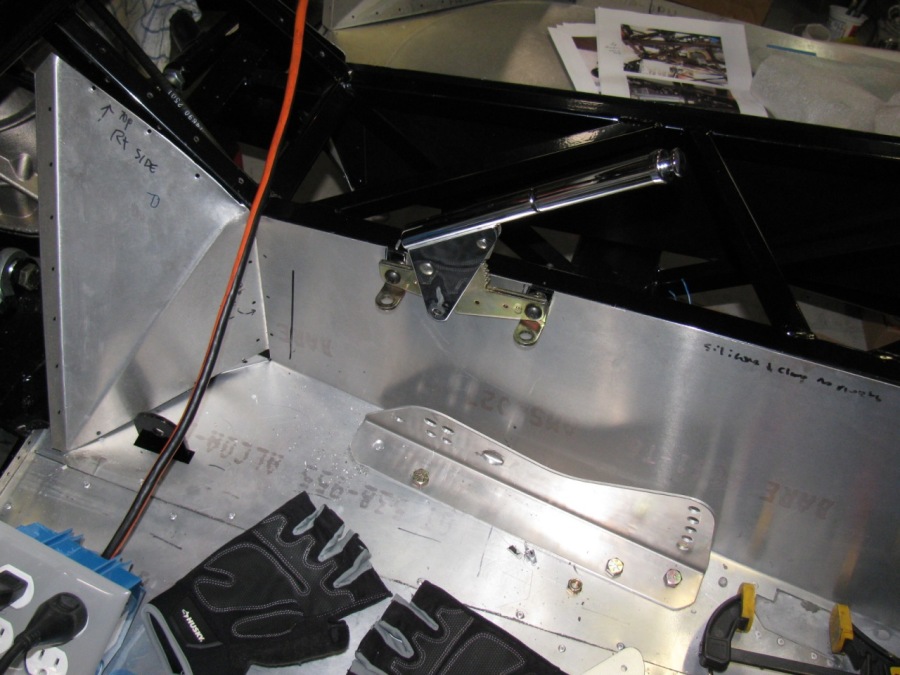

Here is an example of what I mean. I am installing the e-brake handle on my car project. This is a little tricky, since the mechanism must not interfere with the driveshaft and transmission. And it mounts on the inside of the transmission tunnel frame at a certain angle. No template is included in the kit of parts for this e-brake handle mechanism.

Yes, I could measure and mark the hole locations using a combination square and a sharp scribe. But it is much faster to use the mounting flange as a template and drill it in place.

Here is a series of pictures showing how I did this without measuring anything. Remember, no measuring means there are no measuring errors!

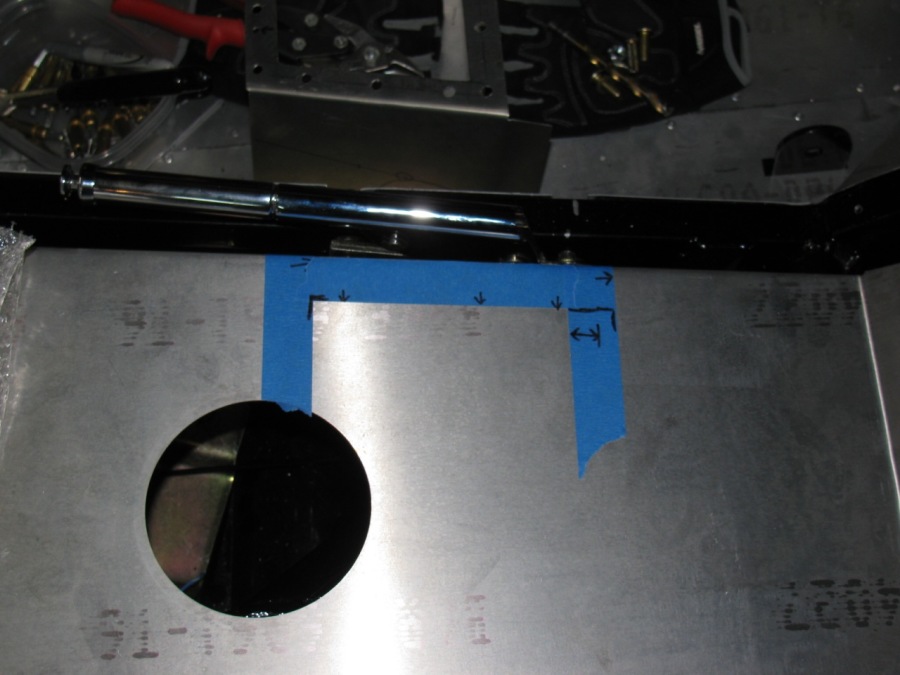

The handle is temporarily held in place with a quick-clamp on the outside of the desired location. The aluminum panel is at an angle to the frame rails inside the transmission tunnel, so the panel must be cut to clear the button head fasteners.

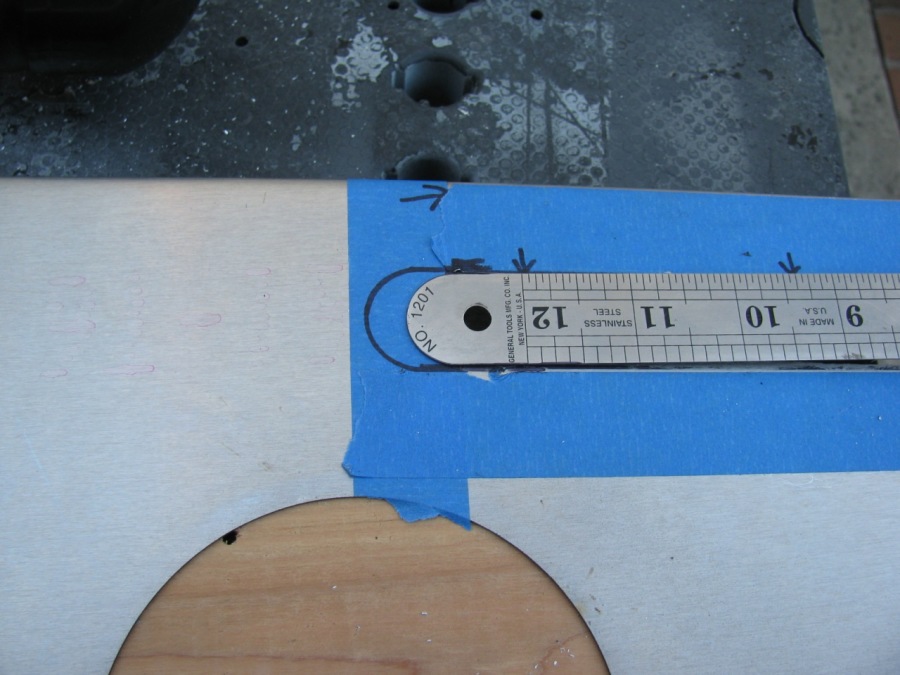

The two mounting holes are used to guide. Rather than drilling the large (5/16-in.) hole, I mark the hole with a “hole sized” twist drill bit first. A soft tap with a hammer marks the location. Then I use an automatic (spring-loaded) center punch, and drill a small pilot hole, maybe 1/8-inch to start. Finally, I ream the hole to the final size with the correct drill bit.

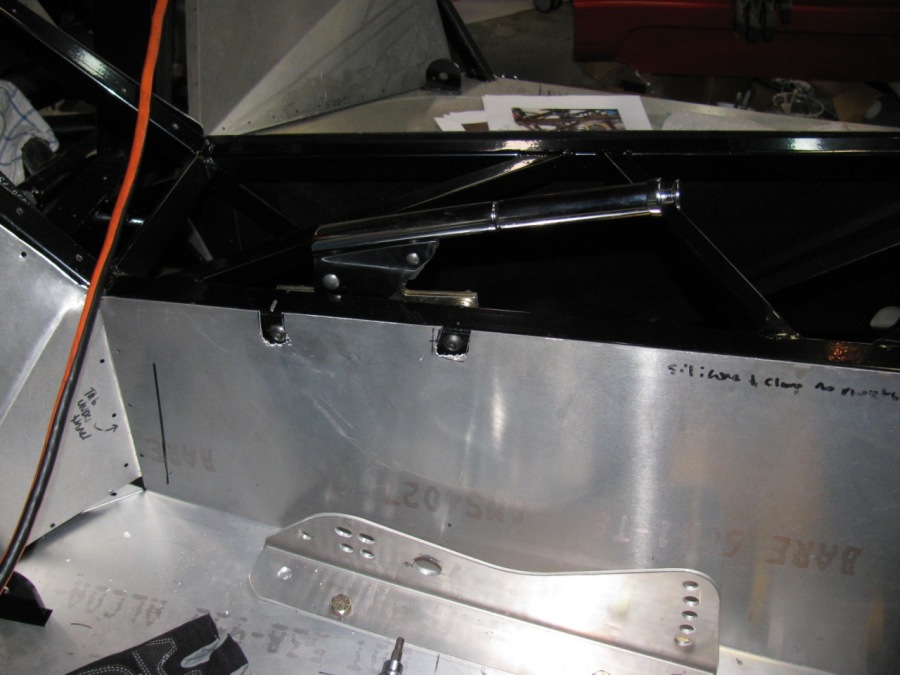

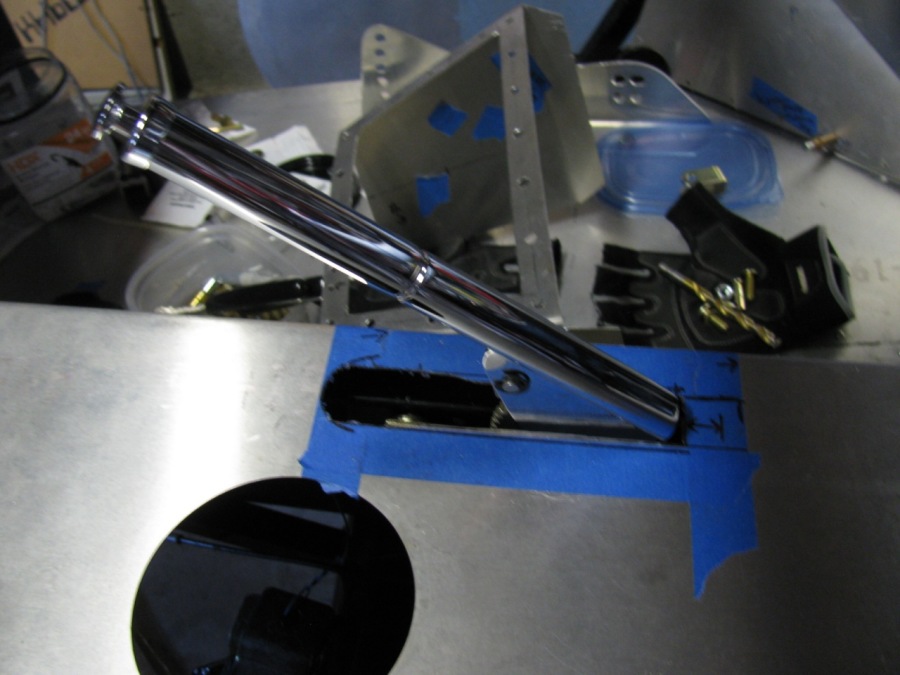

The holes are drilled on the outside of the transmission tunnel, but the handle must be installed on the inside, as shown. The top cover and carpet will hide the bolt heads when the car is finished.

Here’s another picture of the e-brake handle in its final location. The linkage is next.

The handle is bolted in place and the linkage is installed along with the brake cable clevis. The two brake cables are hanging loose in this picture. They will be connected later.

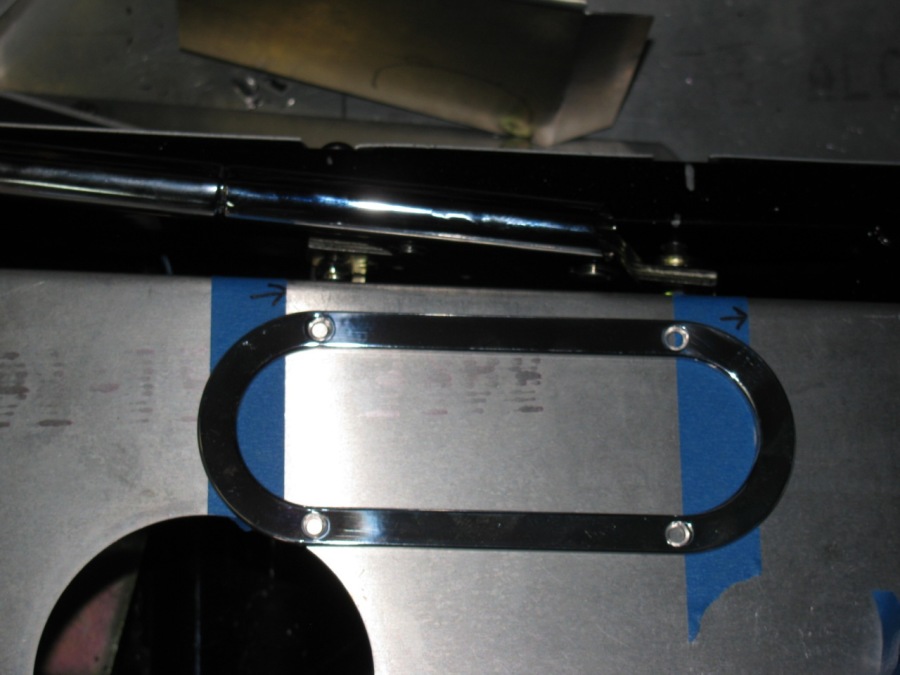

This nice chrome bezel and the e-brake handle boot will cover the hole when this is completed.

Next, the transmission tunnel cover must be cut to accommodate the new brake handle. Masking tape is used to mark the approximate locations for the long, oval hole as well as the frame rails under the cover.

Another “no measuring” technique is illustrated here. The ruler is one-inch wide and has a nice radius at the end, perfect for marking the slot for the handle.

The aluminum panels are fairly thick, so snips don’t work too well. A power jig saw with a fine tooth blade works best.

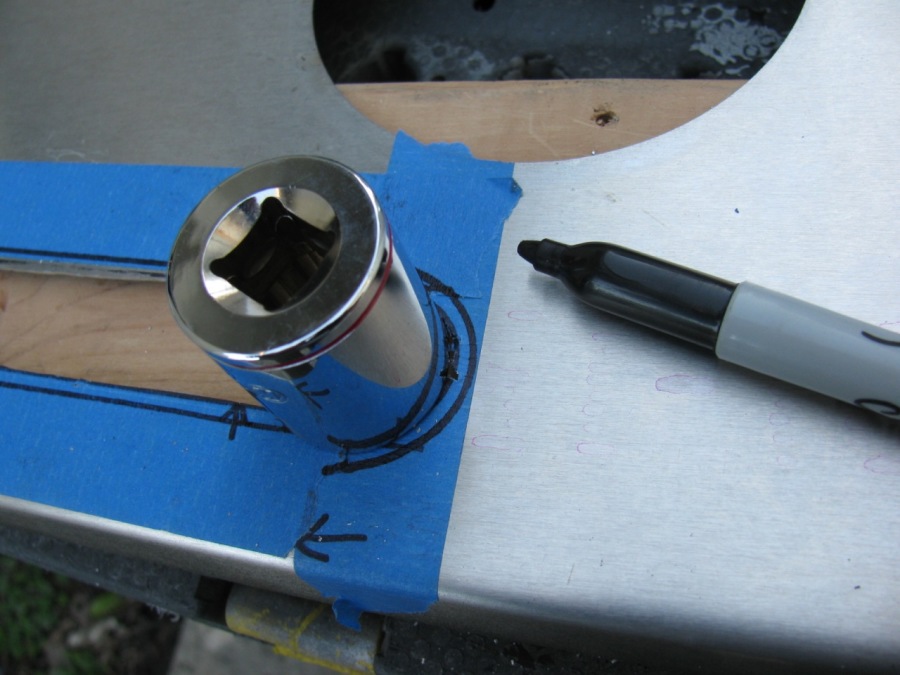

The cut-out turned out to be a little too small, so an additional cut had to be made. (The release button at the top of the lever flares out.) A socket is perfect to mark a wider radius.

I decided to enlarge only the upper portion of the cut-out to accommodate the release button.

The completed cut-out and the bezel temporarily in place. The transmission tunnel will be covered with carpet later.

Here are some other no measure techniques I use all the time:

Quick! What’s the diameter of a 6-32 machine screw? Use your drill bit box as a gauge.

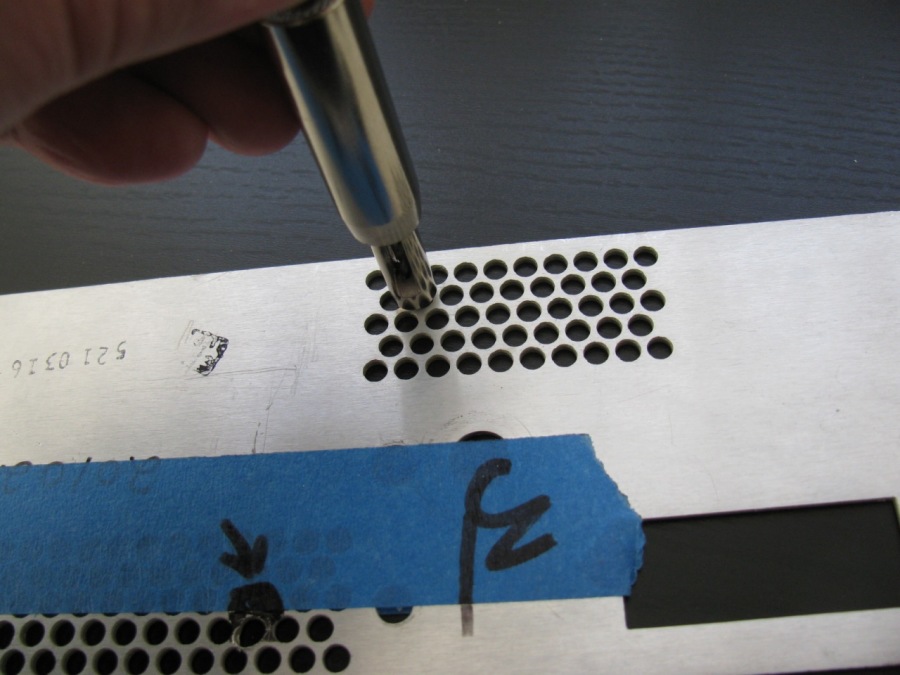

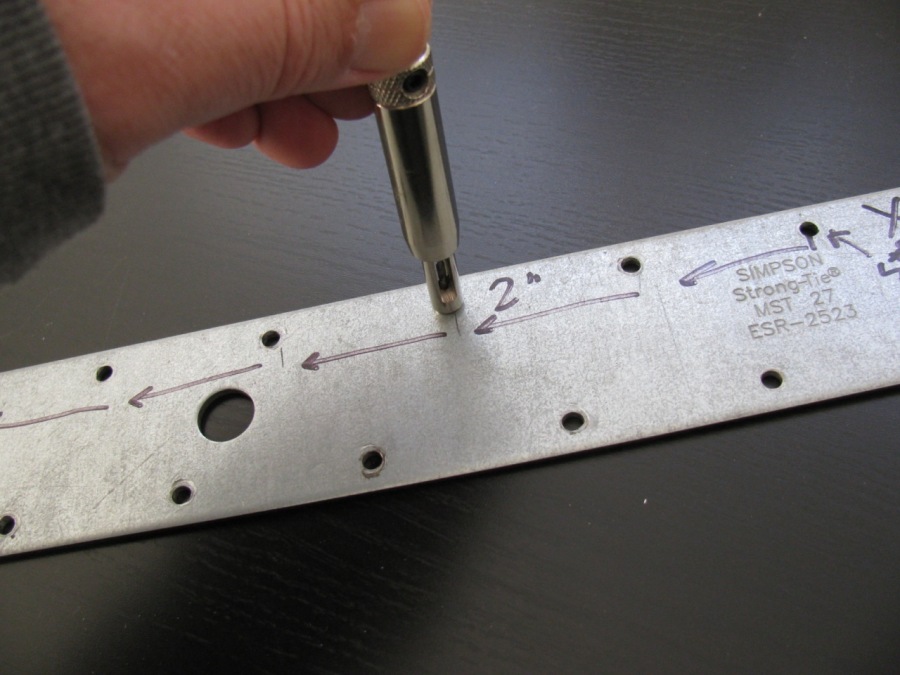

Ever have to drill long rows of evenly-spaced holes in something? And some holes were not exactly in line? Here’s a neat no-measure trick that will make hole patterns beautiful every time.

Use a jig and a self-centering drill bit used by woodworkers for making holes for hinges. I have a set of “the original” Vix-Bits. They are excellent.

Using the Vix-Bit is the first part of this technique. The second part is also critical. Turn a scrap piece of punched metal as a jig to guide the Vix-Bit as shown in the two pictures above.

These tricks will help you become more productive and produce nice-looking results.

And since you did not measure anything, there is no possibility of making a measuring mistake!

Do you have any unusual or handy tricks or tips to share? Let us know in the comments below!

About Wayne Yoshida

Articles from Wayne Yoshida

View blog

Blow your own horns because no one will do it for you. · One of the most important items in your car ...

A few years ago, I made this zero-budget Christmas light controller. It was inspired by an old model ...

Fancy red, orange and yellow bell peppers were on sale last weekend, so I decided to make a batch of ...

You may be interested in these jobs

-

+ · ...

Detroit, MI1 month ago

-

The Senior Manager Consumer Connections MAKERS MARK is responsible for developing and executing strategies to fuel consumer discovery engagement and drive brand loyalty for our US MAKER S MARK category. · Lead the development of comprehensive consumer connection strategies for MA ...

Chicago3 weeks ago

-

This job involves welding and joining metal components or filling holes in fabricated metal products. · Tasks include clamping, holding, tack-welding, heat-bending, grinding and/or bolting component parts to obtain required configurations and positions for welding. · Remove rough ...

Junction City1 month ago

Comments

Wayne Yoshida

9 years ago#1

LOL . . . That was me, too. When making critical cuts, I take a piece of scrap, do my no measuring technique, and make sure it is nice and tight. Then make the real cut. This assumes the tool guide or jig or fence did not move.