Small Solutions... Big Results (No. 1)

![Small Solutions... Big Results

Adventures in Vale | ngineenng No ©

REIS [en [ee]

J Ae erage](https://contents.bebee.com/users/id/10277593/article/small-solutions-big-results-no-1/0d54aeb8.jpg)

THE FIRST IN A SERIES OF RETROSPECTIVES THAT LOOK BACK AT THREE DECADES OF FINDING VALUE-ENGINEERED SOLUTIONS...

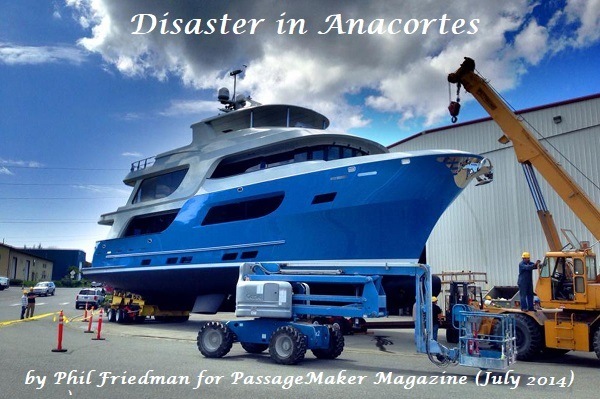

Preface: This article begins a series that looks back at various value-engineered solutions to problems encountered by the author in the course of several decades of boat and yacht building and shipyard management.

Several years ago, I contracted to plan and supervise the ship-fitting of a 45-metre high-performance littoral patrol vessel from the keel to the main weather deck. The work included the first-ever installation of two Hamilton HT1000 waterjet drives in a fiber-reinforced plastic composite hull.Engineering isn't always simply about the design of a product but just as often about the planning and execution of the building of that product...

Phil Friedman in The Portable Boatyard

The drive units, which were capable of absorbing more than 5,000 horsepower each, were massive ― about 13 tons each. Even the cast aluminum water intake grates weighed more than half a ton each. And both the drive units and their water intake grates had to be bedded and bolted to the vessel's composite hull with hundreds of 19mm and 25mm diameter stainless steel cap screws (bolts).

All the drive train components would be highly stressed under loads, hence installation needed to be flawless. In metal hulls, fit-up is fairly straightforward and final attachment is completed by welding the components to the hull structure. But mating metal drive train components to a molded composite hull becomes much trickier ― partly because elastomeric bedding/bonding compounds have to be employed to fully seal the joints, and such compounds have limited working lives once applied.

Another complicating factor is that a molded vessel hull has an outer surface that is smooth and locally uniform, where it has been controlled by the machined inner surface of a female mold (tool).

In contrast, the inner surface is generally undulating and somewhat rough and uneven due to the nature of building up a fiber-reinforced composite structure a layer at a time.This relatively uneven inner surface works against being able to seat properly the load-spreading backup washers in a through-bolt assembly.

Moreover, the sheer number of bolts involved called for very accurate pre-boring of the bolt holes, if there was to be any chance of getting them all to line up fully at final assembly, whilst maintaining minimum clearances in the bolt holes themselves. (Zero wiggle room for lining up at final assembly.) Sounds like a job for a numerically-controlled robot borer, costing perhaps a million or so dollars... right?

Sometimes the biggest results can be achieved with the smallest of solutions...

Phil Friedman in The Portable Boatyard

Instead of looking for a high tech solution, we opted for designing, building, and employing some purpose-specific low-tech tools.

1. We decided to use the castings that needed to be bolted to the hull as self-templates for boring the hundreds of holes required.

2. We designed and built some fully-articulating electro-hydraulic fixtures that would enable us to lift, maneuver, and hold the heavy units in place against the hull while we bored the holes.

Then came the most elegant and inexpensive solution I think I've ever developed for assuring relative boring precision in such circumstances.

3. We had some Delrin bushings machined to fit inside the holes factory-bored into the cast flanges being bolted to the hull. These bushings acted as guides to center and normalize the axis of a 6mm pilot drill bit.

4. We began on each flange by drilling, from the outside inward, four evenly-spaced pilot holes, using the flange as a self-template.

5. We then moved to the inside of the hull and, using a spot-surfacing tool, specifically designed and built for the job, we ground a perfectly centered and very flat round landing area for the wide heavy duty "fender" style washers that would act as backing for the bolted-on assembly.

We built this tool using a standard hole saw and mandrel whose integral pilot bit had been replaced by a smooth 6mm rod. The hole saw itself was stuffed with marine grade plywood filler blocks, cut using the hole saw and built up until the stack stood proud of the saw teeth. This packing stack was then covered with a 16-grit flexible sanding disc. (Cost less than $200 to build a half dozen of these.)

By inserting the pilot rod of the tool in the pilot hole from the inside outward, we were able to grind a perfectly centered and normalized landing flat into the inside of the composite hull skin and, thereby, achieve full contact with the load bearing backing washers.

6. Once the initial locating holes had been bored, we then proceeded to bore and prepare the rest of the bolting holes and insert, on a trial basis, all of the bolts. We then removed all of the bolts except for the four "locator" bolts, which we back off enough to allow the mating surfaces of the hull skin and the casting's flange to be "buttered" with a high-strength elastomeric bedding/bonding compound. After which a half dozen pairs of hands tightened the locator bolts and reinserted and tightened the hundreds of additional bolts (threads bathed in the same bedding/bonding compound) into their respective pre-bored holes ― all completed well within the working time for the bedding/bonding compound.

Every bolt hole lined up perfectly with its mate in the matching casting and every backing washer sat fully flush with maximized contact area on the inside of the hull skin. Later, extensive testing failed to disclose a single leak, proof that, with proper planning and preparation, big results can be achieved well within scheduling and budgetary constraints, provided only that you choose the right small solution. ― Phil Friedman

Author's Notes: This is the first of a series of articles that I believe may be of interest to engineers and tradesman who deal regularly with construction- and manufacturing-related problems and issues. One of my objectives in producing the series is to illustrate how thinking in terms of value-engineering ― seeking to balance cost against first-rate execution ― pays off time and time again.

If you found this article worthwhile, you might want to follow my blog here on beBee, so that you will be notified via email when subsequent installments appear.

You might also be interested in one or more of my eBooks:

Ten Golden Rules for Successful New Build Projects

Small-Business Primer: Real -World Tips for Starting and Running Your Own Small Business

The Portable Boatyard (scheduled to be published late Fall, 2017)

For information on securing a copy of one or more of these, email phil@portroyalgroup.com and put "eBook" on the subject line.

Are you starting up or currently operating a small business and facing a problem or issue on which you could use some help? Consider our offer below:

About me, Phil Friedman: With 30 some years background in small business and the marine industry, I've worn numerous hats — as a yacht designer, boat builder, marine operations and business manager, marine industry consultant, marine marketing and communications specialist, yachting magazine writer and editor, yacht surveyor, and marine industry educator. I am also trained and experienced in interest-based negotiation and mediation. In a previous life, I taught logic and philosophy at university.

#ENGINEERING #ENGINEERINGSOLUTIONS #MANUFACTURINGSOLUTIONS #BOATBUILDING #SHIPBUILDING #MARINEOPERATIONS #MARINEMANAGEMENT #DESIGNSOLUTIONS ##MARINEBUSINESSCONSULTING #SMALLBUSINESS #BUSINESSMANAGEMENT #BOOSTPROFIT #BETTERBUSINESS #BUSINESSCONSULTING #ENTREPRENEURSHIP #STARTYOUROWNBUSINESS #ENTREPRENEUR #BUSINESSSTARTUP #RUNNINGYOUROWNBUSINESS #CASHFLOW #PROFIT #P&L #CASHMANAGEMENT #PROFITVERSUSCASHFLOW #COMPETITIVEEDGE #COMPETITIVEADVANTAGE #STAYAHEADOFCOMPETITION

Articles from Phil Friedman

View blog

A RECAP OF RECENT ARTICLES WRITTEN AND PUBLISHED BY PHIL FRIEDMAN... · Thanks to Don Philpott☘️ whos ...

WILL KICKING BUTT IN THE U.S. HOUSE OF REPRESENTATIVES BE A STEP FORWARD OR TWO STEPS BACK? · Prefac ...

LOOKING BACK AT THIS PIECE I WROTE FOR PASSAGEMAKER MAGAZINE IN 2014, IT SEEMS THAT THE DARK CLOUD S ...

Related professionals

You may be interested in these jobs

-

Customer Service

Found in: Lensa US 13 C2 - 2 hours ago

meerutonline Fayetteville, United States**Work Experience** · Fresher · 1 · 2 · 3 · 4 · 5 · 6 · 7 · 8 · 9 · 10 · 10+ · **Education** · 12th Pass · Graduate · Post Graduate · Doctorate · Other Education · > ** Customer Service Classified Ads in Meerut ( Uttar Pradesh)** · > · > Listing View List Vie ...

-

Middle School Social Studies Teacher

Found in: Talent US C2 - 1 hour ago

Michigan School Public Relations Association Dickinson, United States Full timePosition Details · Norway-Vulcan Area Schools is in search of a full-time, middle school, social studies teacher. · We are a small district located in Michigan's Upper Peninsula, in the Iron Mountain economic zone, about 90 minutes north of Green Bay, WI. Our students rank highl ...

-

cna

Found in: One Red Cent US C2 - 2 hours ago

Decatur County Memorial Hospital Greensburg, United StatesPOSITION SUMMARY Reports To: Unit Manager Summary: Employee is primarily responsible for assisting RNs, LPNs, and Physicians with care of the patients. The employee should be able to think and react quickly in critical situations. The employee performs the duties assigned using m ...

Comments

Lada 🏡 Prkic

6 years ago #33

Phil, thank you for the kind words. Your comment made me think. Perhaps I should trust your guts. :-)

Phil Friedman

6 years ago #32

I agree entirely, Milos, Science and Engineering aren't always just about the "big" stuff, but just as often about understanding and improving the "little" things in life -- like, as you point out, how deep-cycling cell phone batteries reduces their working life.

Phil Friedman

6 years ago #31

Peter> "I'm trying to establish that the term "value engineering" is not a universally understood term.." Ah, Peter, if you had only said that at the beginning of your first comment, my eyes would not be glazing over with this exchange. To be clear, I agree with you that the term may not have a single universally-accepted definition. But then how many such terms do? I believe it sufficient that I used the term in one of its commonly accepted meanings. I am sorry if you mistook what the piece might be about. But it seems to me that the title clearly indicated the article was about "small solutions". Moreover, the lead image reinforces that point, especially in the simulated drawing title box, where it actually describes the object that will be the focus of attention. And if those were not enough to warn you off potential ennui, the first highlighted statement left little doubt. "Engineering isn't always simply about the design of a product but just as often about the planning and execution of the building of that product..." Cheers!

Milos Djukic

6 years ago #30

1. Meaning of “value engineering” in the English Dictionary: "The process of reducing the cost of producing a product without reducing its quality or how effective it is: Substantial value engineering had to be done to control costs." (http://dictionary.cambridge.org/dictionary/english/value-engineering) 2. "Value Engineering (VE) is concerned with new products. It is applied during product development. The focus is on reducing costs, improving function or both, by way of teamwork-based product evaluation and analysis. This takes place before any capital is invested in tooling, plant or equipment." - from article: Value Analysis (VA) and Value Engineering (VE): Definitions and Benefits on advice-manufacturing.com (http://www.advice-manufacturing.com/Value-Analysis.html) 3. "Value Engineering is a systematic analysis method which, when properly applied to a product, process, or service, will reduce costs and increase profit margins. It involves creativity and challenges existing procedures, revealing successful new strategies. It is also known as Value Analysis. The results and techniques are the same." - from McGill University Value Engineering Workshop (http://www.mcgill.ca/ve/) 4. "Value engineering can be defined as an organized effort directed at analyzing designed building features, systems, equipment, and material selections for the purpose of achieving essential functions at the lowest life cycle cost consistent with required performance, quality, reliability, and safety." - from the U.S. General Services Administration (GSA) website (https://www.gsa.gov/portal/category/21589)

Milos Djukic

6 years ago #29

Dear @Peter Altschuler, Thank you for the clarification. Best regards, Milos

Milos Djukic

6 years ago #28

#LETTHEAUDIENCE(including some academics)DECIDE .... The correct and helpful value engineering.

Milos Djukic

6 years ago #27

Phil Friedman

6 years ago #26

No, Peter, you're not just saying. Your seeking to build a straw man argument by assuming a definition of "value-engineering" that serves your own purposes. To wit, a commonly accepted definition of value engineering is, "Value engineering (VE) is a systematic method to improve the "value" of goods or products and services by using an examination of function. Value, as defined, is the ratio of function to cost." The particular example I chose here illustrates the performance of a particular operation necessary during the construction of a high-tech military vessel, under a NAVSEA government contract, at a cost far below what was expected or budgeted. Sorry, if that strikes you as too mundane to be of interest, but frankly that is the reaction of a writer who talks about such things, not that of anyone who is a shop-floor veteran, engineer or otherwise. In this context, I am happy to ... #LETTHEAUDIENCEDECIDE Cheers!

Phil Friedman

6 years ago #25

No, Peter, you're not just saying. Your seeking to build a straw man argument by assuming a definition of "value-engineering" that serves your own purposes. To wit, a commonly accepted definition of value engineering is, "Value engineering (VE) is a systematic method to improve the "value" of goods or products and services by using an examination of function. Value, as defined, is the ratio of function to cost." The particular example I chose here illustrates the performance of a particular operation necessary during the construction of a high-tech military vessel, under a NAVSEA government contract, at a cost far below what was expected or budgeted. Sorry, if that strikes you as too mundane to be of interest, but frankly that is the reaction of a writer who talks about such things, not that if anyone who has worked as a shop-floor veteran, engineer or otherwise. #LETTHEAUDIENCEDECIDE Cheers!

Milos Djukic

6 years ago #24

Milos Djukic

6 years ago #23

Thanks Phil.

Milos Djukic

6 years ago #22

Just guess Peter, I could write an article on how to fight against hydrogen embrittlement and the environmentally-enhanced cracking of military equipment, including naval ships and fighter. This seems like a very important technological breakthrough, but it is not. Social media is not the ground for such "so-impressive value-engineered solution". Finally, an article like this one by Phil has great practical value and certainly represents a practical and useful example of a successful engineering in a specific field. Science and engineering are not only in national laboratories and large research centers. The work of engineers is also practical. Just my 2 cents.

Phil Friedman

6 years ago #21

Thanks, Todd Jones, for reading and the kind words. Plugs for the intake holes were placed in the female tool by working from the CAD drawings. A male plug placed in a female tool leaves a hole in the molding when it is removed from the tool. Same for the waterjet drives, which were inserted through holes in the transom. We built special purpose alignment jigs for the intake grates which had a vertical spike that extended up into the hull and which had to kiss a laser light beam from a jig on the transom in order for us to know that the waterjet units could be buckled up to the intake ducts/grates. A lot of measuring, laser projecting, etc. However, you need to keep in mind that the only really tricky part was to assure that the drive would couple properly to the intake ducts because the engines were coupled to the drives via Cardan shafts (a long jack shaft with a constant velocity universal joint at each end. I will tag you, as requested, for subsequent installments of the series. Thanks and cheers!

Phil Friedman

6 years ago #20

Lada \ud83c\udfe1 Prkic, much of my writing has been in the interpretation of technical material for an educated, though not necessarily technically oriented audience. I've found the effort gratifying, and my gut tells me you would too. Moreover, your English is beautify and flawless. So if you were to feel the need for a cooperating copy editor, I'd be pleased to helpin any way I could. Not pressuring you. Not pressuring you. Not pressuring you. Cheers!

Phil Friedman

6 years ago #19

That's why, Graham, I believed this might have some wider appeal to even those who couldn't care less about grinding perfect flats for backing washers. In this case, I think the lesson(s) transfer to business management, as well. Thank you for reading and commenting. Cheers!

Phil Friedman

6 years ago #18

Ah, Jerry, you correctly perceive that there is an undercurrent of life philosophy running through this engineering-related piece. Thank you for reading and commenting with such insight. Cheers!

Phil Friedman

6 years ago #17

Milos, I appreciate the suggestion and already planned to do so -- eventually. What I've discovered, however, is that simultaneously sharing a piece in a number of groups breaks up the "trending" stats among the group notices and tends to retard distribution in the main feed. (LI worships trending and so gives better distribution to what the Algirithm sees as more popular articles.) So better to wait for sharing into groups until the initial rush of views and likes is complete and the piece sits on the LI "long tail". Cheers!

Phil Friedman

6 years ago #16

Except, Peter Altschuler, that would not satisfy those who tend to start reading at the end in an effort the glean the crux without the work of reading through the piece. Oh, and BTW, with all due respect, what is not clear about my deck and preface which said: "THE FIRST IN A SERIES OF RETROSPECTIVES THAT LOOK BACK AT THREE DECADES OF FINDING VALUE-ENGINEERED SOLUTIONS ... This article begins a series that looks back at various value-engineered solutions to problems encountered by the author in the course of several decades of boat and yacht building and shipyard management. "? Anyway, thanks for reading and commenting. Cheers!

Lada 🏡 Prkic

6 years ago #15

To write a serious technical article requires a lot of time and effort. Also important is the existence of an audience for such writing. I don't want the non-technical reader's eyes starting to glaze over after only a few paragraphs. :-)

Graham🐝 Edwards

6 years ago #14

Jerry Fletcher

6 years ago #13

Wayne Yoshida

6 years ago #12

Phil Friedman

6 years ago #11

Lada \ud83c\udfe1 Prkic, please do not give up on writing. I, for one, would be fascinated to read about some of your past projects. Cheers!

Phil Friedman

6 years ago #10

Lada 🏡 Prkic

6 years ago #9

David B. Grinberg

6 years ago #8

Milos Djukic

6 years ago #7

Phil, I think that's a good idea. Nevertheless, I love your writing in all its forms, but please publish this series also on LI and within some groups about the marine industry and yachting. Just my 2 cents

Phil Friedman

6 years ago #6

Thank you, Don, seriously, for reading and commenting. Yes, I think an important component in the lesson is that simple is often very powerful. Both in Industry and in life, don't you think?

don kerr

6 years ago #5

Phil Friedman

6 years ago #4

Thank you, Gert Scholtz, for reading and for saying so. I have been looking forward to turning my writing back onto technically-related matters. Cheers!

Gert Scholtz

6 years ago #3

Phil Friedman

6 years ago #2

Milos Djukic

6 years ago #1