Maturity and Continuous Improvement

“You are only young once, Alan, but you can be immature forever.” I’m not sure who first said this to me, probably some elementary school teacher upset by my constant “cutting up” in class. I’ve heard it from several managers over the years, who recognized that my “humor” was a thinly disguised “problem with authority.” Now, in my relative dotage, I’ve taken it as a guiding principle for my life.

“You are only young once, but you can be immature forever.” This is definitely NOT true for continuous improvement initiatives.

Implementing Continuous Improvement, (CI) like all change in organizations, is a race against entropy, gradual deterioration and decline. CI is a discipline, a mindset, and a set of tools that take a while to learn, but falls into disuse quickly.

Organizations are composed of people and people are forgetful and easily distracted. So a set of competencies that are somewhat hard to learn and difficult to practice, can become an burden, then the subject of mockery and displaced by some other concept, then “ancient history” to which most are indifferent. So quickly building the self-reinforcing CI habit with a critical mass of the organization is critical to maturity in continuous improvement.

What is CI?

CI is a structured methodology for performing better. Fundamentally it’s

“Measure where you are – analyze why – improve – measure where you are then”

Then repeat that process - continuously.

There are many versions of this methodology, Total Quality Management (TQM) Six Sigma, Lean, Lean Six Sigma, Statistical Process Control, Re-Engineering, Process Improvement. My Results-Alliance colleague, Ric Taylor and I have implemented CI in many of these guises.

We have now become “methodology agnostic.” Just pick one. Using multiple methodologies is an advanced concept, akin to the concept of “spin,” in tennis. “Just concentrate on getting the ball over the net and between the lines, Alan. You can work on ‘cutting’ it later.”

What is CI maturity?

A CI initiative is mature when it is sustainable. The CI implementation process is “systematic and in control.” The improvement process is:

- Targeted strategically,

- Documented, well understood, and practiced,

- With clear accountibilities for who does what, (including monitoring and responding to deviations to the improvement process)

- Demonstrated competencies for each accountability.

- Organizational policies, procedures, systems and structures ensure results and improvement.

In short, the organization is improving in the metrics it has targeted and it is very likely to continue improving.

To CI practitioners, it will be obvious that this is maturity from a process point of view.

The outputs are the improvements – strategically directed (the ‘right improvements’) – measureable – sustainable and improving over time.

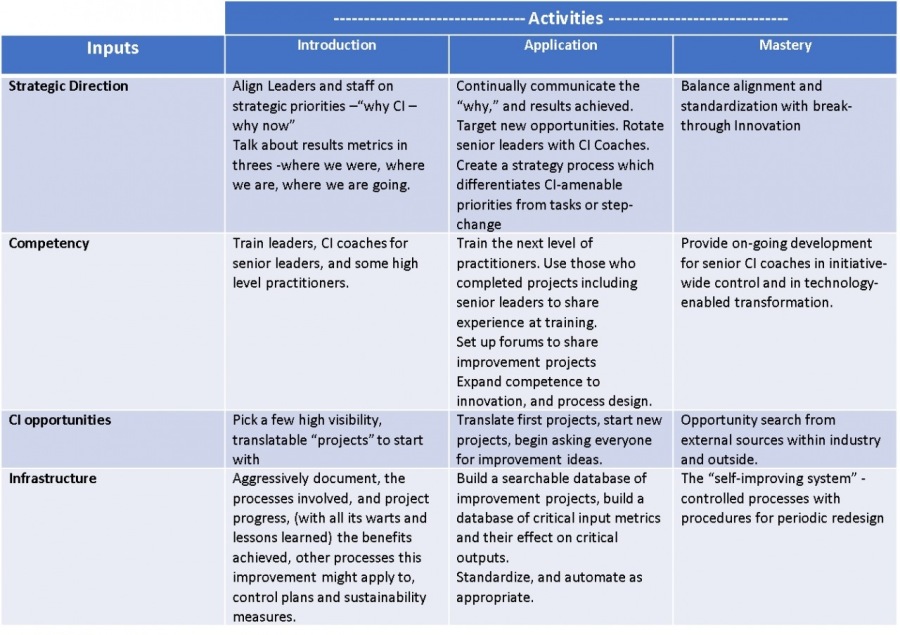

The inputs strategic direction – competency (knowledge and skill) – improvement opportunities (defects, problems, gaps, targeted projects) and supporting infrastructure (policies, procedures systems and structures)

The activities change over time as the organization learns this process and evolves towards maturity.

There are other staged learning models. The building trades have Apprentice, Journeyman, Master; some religious orders are divided into novitiate, postulant, nun or monk; Six Sigma adopted the belt system of Asian martial arts, Green Belt. Black Belt, Master Black Belt. The progression is one of learning:

- Introduction – often learning from a teacher,

- Application – learning from practice,

- Mastery – learning by teaching others.

In many disciplines master or sensei is a designation of respect by the student for the teacher, not a title assumed by the master, who feels she is still continually learning. Humility is fundamental to mastery.

Let’s think about the activities of implementing CI in these three learning stages. The table below illustrates ideas for progressing from Introduction to Application to Mastery, without intending absolutes or hard lines between learning phases. From what I’ve seen every organization is unique.

Here are a few take-aways from this table:

1. Start with strategic direction. Far too many CI implementations start with training and a few projects first. They then try to “loop the leaders in” later. This is a cause of a lot of wheel spinning and actually may be the cause of the “flavor of the month” phenomenon.

2. Start small. Ensure that you get improvement in the areas you target.

3. Pick replicable projects. Working on the accounts receivable process for one product line can be copied easily for another product line. I frequently tell training classes that the real money in CI isn’t in the first project, but in the second, third, or fourth project in the same area. It gets easier, less resource-intensive, and the results get bigger.

4. The key to sustainability is documentation. Keep records of processes, projects, key inputs and their impact, your successes and most especially your failures. Continuous improvement is about continuous learning.

5. Mastery is about teaching others. CI specialists are not enough. Leaders must become teachers. That is the way CI gets integrated into the culture of the organization.

I’m often asked, “How long does it take to implement CI?” The answer is the same as the answer to the question, “How long will it take to lose x pounds?” “It depends.”

How long it takes to implement CI, depends upon, where the organization is today. (This is a partial list.)

- Are we process-focused OR activity-focused, managing the organization from a to-do list?

- Is there a real hunger for learning OR are we stuck invested in “the way we’ve always done it?”

- Have we had success at making large scale change OR do we constantly gravitate to the latest “management fad?”

Each of these questions present two different current states. The latter state lengthens the time it will take to become mature at Continuous Improvement.

I have seen organizations get to consistent application in a relatively short period of time, 3-5 years. I’ve seen some organizations struggle for 10 years or more to get to the same place. By then, these organizations are fighting a continuous battle against deterioration. Many give up or move on to the next fad.

Getting to mastery takes longer. Toyota started developing the Toyota Production System in 1948 and we’ve been talking about it since 1975, more than 40 years. I’m not sure that Toyota would say they’ve reached mastery.

It is a continuous journey, but as Lao Tzu said, “Even a journey of a thousand miles, begins with a single step.”

"""

Articles from Alan Culler

View blog

It’s New Year’s Eve Eve and as I look back at last year’s resolutions I realize I still have two day ...

“Those who came before us had the knowing and the doing beyond our ken.” · My wife and I visited New ...

Change Leader? Who Me? Hard-Earned Wisdom for Those New to Leading Change · is finally published. He ...

You may be interested in these jobs

-

Continuous Improvement Leader

6 days ago

Hexcel KentWe invite you to join the Hexcel team at various manufacturing sites, sales offices and R&T centers around the globe. Become a part of the "strength within." · Bachelor's degree in Business Administration, Engineering, Operations Management, or related field with a Six Sigma or L ...

-

Continuous Improvement Manager

1 month ago

Eaton NacogdochesThis role is responsible for supporting plant leadership in achieving business and financial goals by leading continuous improvement /cost out initiatives across the plant. · The expected annual salary range for this role is $ 80k - $ 120k per year.This position will be the champ ...

-

Continuous Improvement Manager

22 hours ago

LensaThe Continuous Improvement Manager will drive increased performance across the network through the execution of proven behaviors and activities. · Address identified operational issues at action plan or non-performing stores · Conduct training, consulting and coaching · ...

Comments