A Continuous Improvement Initiative Roadmap

Measure where you are today (baseline)

Understand the causes and plan to improve

Measure the improvement

Repeat

CI is easy to understand conceptually, but it is a discipline that requires consistent practice –think about martial arts or learning to pay the piano. There is a mindset –it starts with thinking about numbers not as individual numbers, e.g. a task takes “3 minutes of cycle time” to complete, but in comparison to other numbers, e.g. "It took 3 minutes of cycle time to complete today, which is down from 3 ½ minutes yesterday.” Or the cycle time could be compared to a similar process

CI is most often used in improving business and operational processes. A process is simply a set of activities with the inputs and outputs of each activity step.

I have written elsewhere about developing process focus. It isn’t rocket science, but once you begin to see the world this way the combination of process focus, thinking about measurement and comparing metrics to see trends, is a driver to wanting to improve.

Implementing Continuous Improvement across the organization requires Leadership focus and commitment, using one consistent methodology or framework, and of course measuring inputs, activities, outputs and, of course, results.

A CI initiative often has a start-up expense, but becomes self-funding (paid for by revenue increases, and cost savings) in a year. That doesn’t just happen automatically. It takes discipline and practice.

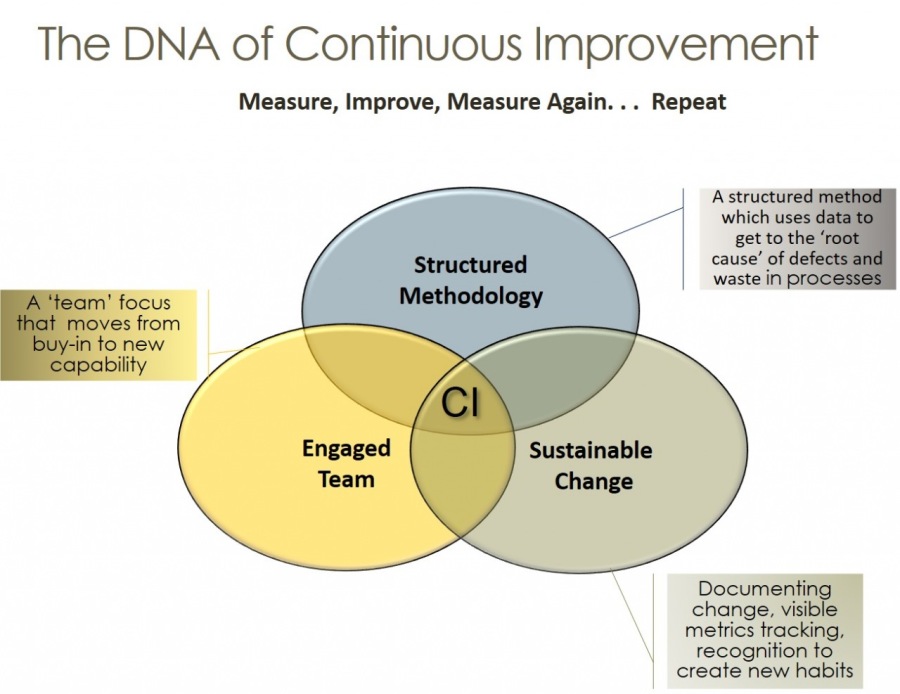

As I mentioned, a CI initiative can come in many forms, each with their own language and frameworks. The all have an underlying DNA.

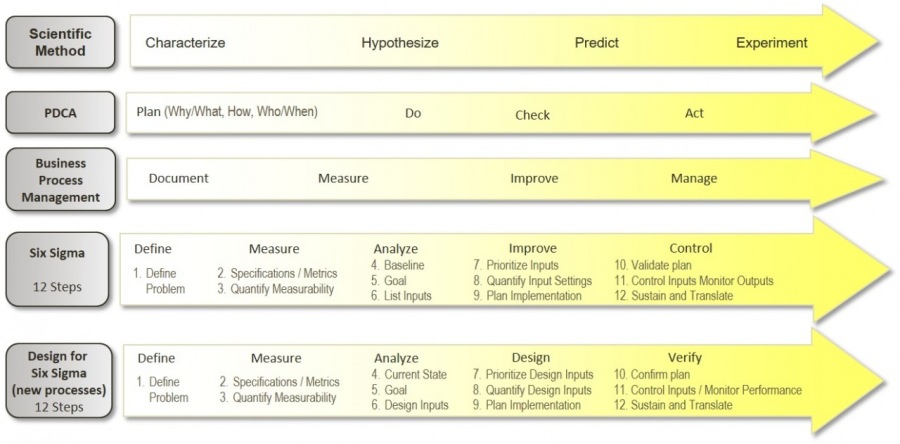

Structured Methodology? Continuous Improvement methodologies tend to differentiate themselves by the problem solving model they use. Over the years my Results-Alliance colleagues and I have become methodology agnostic. You have to use one and only one, but we’ve formed the view that it doesn’t really matter which one. Here are a few:

Most of these have 4-5 basic categories; some have up to 25 steps. We have even designed custom models for clients who were so driven by their “uniqueness” that they wanted to have their own problem solving model. Pick one. What’s important is that your organization is aligned around one. It makes communication so much easier.

Why Teams? One can do a CI project individually, but it is easier to do larger projects in teams to spread the work and reinforce each other’s learning and discipline.

Change? Improvement is change and the point is not to revert to previous performance levels after improvement. This takes some hard tools like control charts and response plans and some soft change management skills as well.

How to Get Started?

1. Leadership Commitment

As with most change efforts it is best to start with leadership. Make sure leaders agree what should be improved and why and communicate clear connections to strategic priorities.

Ensure alignment on chosen methodology, expected outcomes, set up and infrastructure funding, roles, responsibilities and rewards

2. Train resources

These are skills that ultimately everyone can and should learn, but some good roles to start with are:

• CI specialists to lead and staff projects

• Senior CI process experts who help leaders pick the right projects, troubleshoot projects and coach teams

3. Build Infrastructure

Initiatives like this must have supporting systems and processes. A few to think about are:

a. Projects, metrics, and control plan databases

b. A consistent instructional toolkit

c. Benefits tracking

d. Rewards and celebration

Pitfalls - what can go wrong?

Unfortunately, lots of CI initiatives fail. I have written elsewhere about some resistance to CI and what to do about it. There are some common pitfalls:

- No Improvement mindset. Often people are task focused not process focused; often people think of numbers as a one-time event. This is exacerbated by goal setting systems and to-do lists. But if the improvement mindset doesn’t exist, start by building it.

- CI is for Them not us. Often leaders “delegate CI.” That never works. Leaders have to start and run projects like everyone else.

- CI is for Us not them. CI specialists are a good place to start, but creating a special class of people who do the improvement is death to CI. Six Sigma Black Belts higher level of skill is a good thing, but only with Green Belts and Yellow Belts to help mae improvements.

- It’s all about the certification. I’m all for recognition of skill development, but if this becomes more important than the actual improvement, then the organization is just helping specialists move to their next job.

- It’s all about BIG projects. In CI training I often say that the real money in CI is in the second and third projects in the same area. Being able to “translate solutions without reinventing the wheel is the biggest gains come from.”

CI isn’t rocket science or brain surgery, but it does take some practice. If an organization sticks with the disciple cost reductions of 30% and similar revenue increases are not uncommon. For those of us in the field, this seems like it should be a no-brainer. I would that it were so.clear connections to strategic priorities.No clear connections to strategic priorities.

""""Articles from Alan Culler

View blog

Image: Construction of the Steve Jobs Theater, Apple "Mothership," new headquarters Cupertino, Calif ...

Heath Ledger, Mark Addy, Paul Bethany, Laura Fraser, and Alan Tudyk in the 2001 Columbia Pictures Fi ...

A fun and fascinating read on early psychedelic research · “My book about Tim is up on Amazon. I hop ...

Related professionals

You may be interested in these jobs

-

ultrasound tech i central va imaging

Found in: Talent US C2 - 1 day ago

Centra Health Lynchburg, United States Full timeProduces ultrasonic recordings of internal organs for use by physicians, and according to established protocols and American College of Radiology (ACR) guidelines · Provides sonogram and written summary of technical findings to radiologist for use in medical diagnosis · Decides w ...

-

Retail Sales Associate Part Time>

Found in: Lensa US P 2 C2 - 1 day ago

PetSmart Fayetteville, United States Part timePetSmart, Inc Pavilion Pkwy [Sales Associate / Team Member] As a Retail Sales Associate at PetSmart, Inc., you'll: Welcome customers to the store, facilitate an easy check out process as a cashier; Ensure the safety of all living pets in the stores, including fish, reptiles, bird ...

-

Accountant Analyst

Found in: Lensa US 4 C2 - 1 day ago

Intel San Jose, United StatesJob Description · Intel - A chance to work at the leading edge of technology? You know that we are a silicon technology company, but you may not know about the breadth of our innovation. We are expanding the boundaries in Data Centers, AI, Automated Vehicles, Memory, Software an ...

Comments

Alan Culler

7 years ago #3

@Jared Wiese Thanks for your comment. I appreciate the support.

Alan Culler

7 years ago #2

Thanks so much for your comment @AliAnani -Love CE (continuous effort)

Ali Anani

7 years ago #1